How to Reduce Freight Cost

Strategies to Reduce Freight Costs

Shippers often assume that their freight shipping methods and associated costs are rigid and unchangeable, but challenging the status quo can lead to significant savings. At Translogistics (TLI), we've identified numerous strategies to reduce freight costs, which you can start implementing today. From offering drop trailers to carriers to utilizing mode optimization and least cost provider tracking, simple changes can result in savings of up to 50% compared to traditional freight charges. Below, we provide specific suggestions to cut freight costs, along with estimated savings potential.

Launch a Transportation RFP

When your carrier anticipates consistent collaboration and a steady flow of freight along the same route, they can leverage backhauls and expand their network, leading to increased efficiency and lower costs for you. Additionally, in today's market with ample capacity, carriers are inclined to engage when TLI initiates transportation Request for Proposals (RFPs) on your behalf, allowing for customized pricing. Loyalty and reliable freight volumes attract carriers even during periods of tight capacity, ensuring priority of your freights movement.

Potential savings range from 3% to 12% compared to traditional lane pricing.

Ship only on off-peak days

Shifting your shipping schedule by a day earlier or later can result in significant cost savings, particularly noticeable in the Full Truckload (FTL) market, where drivers aim to avoid weekend layovers for shorter hauls. Fridays often experience reduced shipping activity for consumer goods, as retailers strive to stock their shelves by Thursday for weekend sales, while Mondays typically witness low freight volumes, presenting opportunities for carriers seeking loads. However, the suitability of off-peak shipping depends on the nature of the cargo, with non-perishable goods offering more flexibility than perishable items. Opting for off-peak shipping represents an advantageous choice for shippers of non-consumer goods, potentially leading to savings of up to 10% compared to peak shipping days.

Ship in a LTL consolidation program

Consolidation presents an obvious choice - by merging your Less Than Truckload (LTL) shipments with those of neighboring companies destined for the same major retailers and grocery chains, everyone benefits. Through consolidation, suppliers like you pay only for their portion of a more cost-effective Truckload (TL) shipment. Retailers, in turn, receive timely deliveries and benefit from receiving the same volume of goods in fewer, fuller loads, enabling them to optimize dock space and reduce labor expenses. To find suitable shipper-partners, collaborate with a third-party logistics provider (3PL) such as Translogistics, offering a freight consolidation program catering to multiple companies shipping to the same regions.

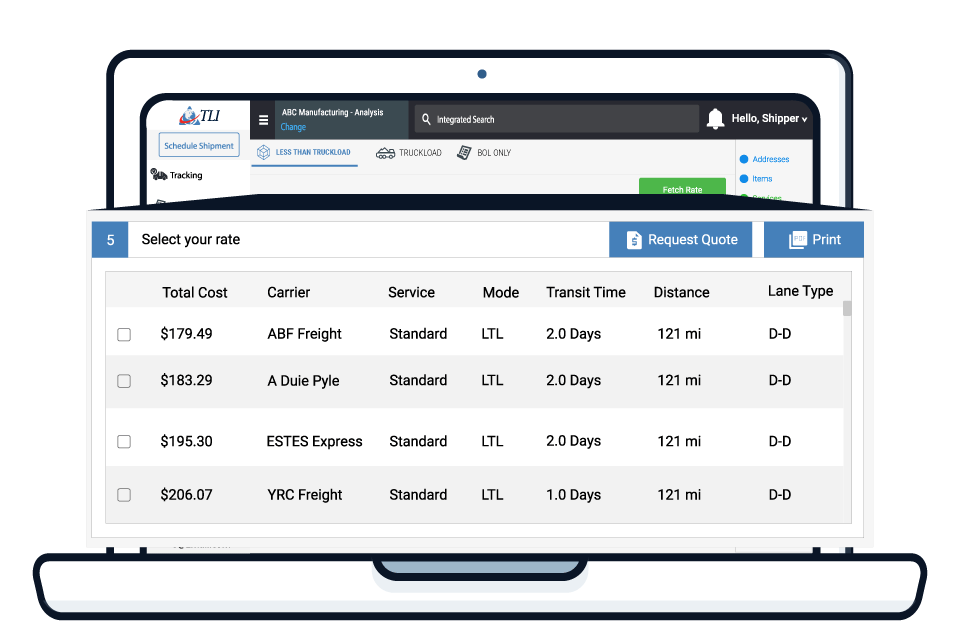

Shop rates, and develop carrier relationships

While participating in the yearly RFP process may seem necessary to demonstrate a commitment to reducing freight costs, continually severing relationships and engaging new carriers annually can disrupt operations. This approach mirrors "speed dating" in the transportation industry. Shippers can gain significant transportation management advantages and bottom-line benefits by fostering strategic, longer-term relationships with carriers.

Longer carrier contracts enable carriers to optimize their networks by attracting additional customers, reducing deadhead miles, and enhancing profitability, which in turn leads to better rates for shippers. Locking in rates for a longer period, such as a two-year contract, prevents annual rate fluctuations and promotes better service from committed carriers. Additionally, showing respect and consideration to vendors, including drivers specifically, fosters positive relationships and enhances overall value. Adopting a strategic, long-term mindset not only results in potential savings of 3-5% annually but also positions shippers to double these savings when capacity tightens.

Increase shipment delivery lead times

Introducing planning into the supply chain and providing advanced notice to carriers about future loads allows them to optimize assets such as trucks, drivers, and warehousing space. An advance shipping notice enables carriers to align resources efficiently, minimizing the costs associated with idle trailers waiting for loading. With improved planning across all supply chain aspects including pickup, staging, and live-loading, carriers can enhance efficiency and potentially offer better pricing by reducing idle time, mitigating detention fees, and operational inefficiencies. The longer the notice provided, the greater the opportunity for carriers to optimize operations behind the scenes, potentially resulting in

savings ranging from 5% to 20%.

Reduce dunnage

Many products necessitate the use of air bags, strapping, blocking, and bracing to prevent damage during ocean voyages or long-distance truck journeys. However, some shippers tend to overprotect their products, resulting in excessive dunnage. Carriers can assist in optimizing dunnage to reduce shipping costs without compromising product safety. Seeking their advice is crucial. Moreover, carriers often employ dimensional weight pricing strategies that incentivize shippers to use appropriately sized packaging, thereby reducing box weight and dunnage. Implementing these strategies can lead to potential savings of 1% per load.

Load the carriers quickly

When carriers establish pricing, they generally assume a 2-hour load window, but efficient loading practices can influence rates positively. If a carrier anticipates quick loading within an hour, it impacts pricing and creates stronger relationships with the shipper. Consistent load time performance can even result in favorable load times being integrated into the rate, eliminating the need for chasing down additional charges. Operating efficiently not only saves shippers money but also attracts carriers seeking to serve efficient shippers, offering a dual advantage. The potential savings depend on the shipper's current reputation, but typically carriers factor in at least $75 per hour into their rates for each hour required for loading.

Offer drop trailers, and later pick-up times

By offering pick-up times later in the day, typically between 6-12 p.m., shippers can provide carriers with an opportunity to turn their load into a backhaul. For instance, a carrier might decline a mid-afternoon pick-up request due to conflicting schedules, but a later pick-up allows them to fill their backhaul with the shipper's freight. This approach aids carriers in maximizing asset utilization, particularly for longer hauls. Additionally, if the shipper has available space at their dock and maintains consistent shipping volumes with the carrier, they can offer to have the carrier drop a trailer for convenient pick-up. This arrangement leads to cost savings and provides carriers with greater scheduling flexibility around the shipper's supply chain needs. The potential

savings from these practices can amount to 15-20% off standard rates.

Minimize the number of pallet spaces

Improving product cube optimization, strategic stacking, and utilizing different boxing methods all contribute to maximizing cargo density on pallets and trailers. For example, placing small components in large boxes reduces pallet efficiency, while using smaller boxes allows for better pallet utilization and space savings. Shippers can consult their LTL carrier for recommendations on building more efficient pallets, tailored to the specific type of product being shipped. Potential savings from these practices can easily reach up to $150 per pallet space.

Ship more product, less often

Promote larger orders among customers as shipping six pallets at once is significantly more cost-effective than sending two pallets every two days. Although retailers often prefer smaller shipments, incentivizing larger inventory orders is essential. One approach is to offer to share freight savings with the retailer, while another option is to implement Vendor Managed Inventory, where the retailer is charged only upon shelf placement. Focusing on inbound raw material and inventory replenishment streamlines operations, making it easier to fulfill customer orders efficiently. These strategies can result in potential savings of up to 50% compared to shipping the smallest LTL loads, where minimum charges may apply.

Make sure your 3PL farms new carriers

Ensure accountability with your 3PL by confirming their utilization of reputable carriers and incorporating new players when opportunities arise. By doing so, your load becomes more attractive as a backhaul, potentially leading to lower rates. Filling empty miles is a profitable strategy for carriers and an effective means for you to reduce freight costs. Implementing these practices can result in potential savings of up to 20% compared to non-backhaul rates for that specific lane.

Involve your logistics team in packaging decisions

These freight packaging factors affect trailer cube optimization. Packaging costs are minimal, constituting less than 10% of supply chain expenses, with warehousing at 25% and transportation at 60%. Hence, it's prudent to prioritize packaging design and carton sizing for freight efficiency. Marketers making these decisions may not consider this financial perspective. Many companies overlook packaging optimization and its effect on freight rates. Potential savings: 10% on total packaging costs.

Outsource your transportation department

It's clear: shippers focusing on their core competency can achieve faster scalability and growth. For smaller shipping companies, freight management isn't a core skill. Managing transportation staff, systems, and driver forces is costly and time-consuming. Outsourcing freight management transfers these financial burdens and enables access to innovative solutions suggested by adept carriers. Large enterprise shippers benefit from TLI's expertise, offering optimized routing, forecasting, pricing consistency, automated invoicing, and ERP integration. Collaborating with industry experts enhances carrier efficiency. For those owning trucks, consider outsourcing freight to cut costs. Potential savings: 3 to 5% of transportation freight costs. Shippers with their own fleets often pay a 25% premium compared to outsourcing to reliable carriers.

How to improve freight rates.

In summary, Translogistics offers numerous ways to save on freight rates, including dynamic routing guides for optimized cost savings, freight invoice audit mitigation, and reimbursement for settlement fees from freight claims. Despite the apparent benefits, many shippers overlook these solutions due to adherence to outdated rules and processes. It's essential to assess your freight program critically, challenge assumptions, and embrace innovative approaches to shipping. By challenging the status quo, significant savings and appreciation can be realized. It's time to ship smartly with TLI!

TLI Insights

Get the latest logistics insights and tips from TLI's award-winning team. Stay ahead in transportation planning.

Questions? Email us at marketing@shiptli.com